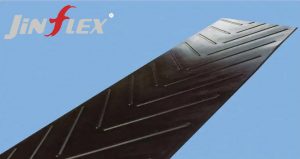

Bucket elevator conveyor belt (also called bucket elevator conveyor belt) is mainly used for vertical conveying of materials. The structure usually includes:

1. Cover layer:

Upper cover layer: located on the working surface of the conveyor belt, in direct contact with the material. This layer is usually made of wear-resistant, heat-resistant, oil-resistant or other special materials (such as rubber or PVC) to adapt to different types of materials and working environments.

Lower cover layer: located on the non-working surface of the conveyor belt, mainly used to protect the internal reinforcement layer. This layer is usually made of the same or similar materials.

2. Reinforcement layer:

Fabric layer: Common reinforcement materials are multi-layer fabrics, such as cotton canvas, nylon canvas, polyester canvas, etc. The function of the fabric layer is to enhance the tensile strength and tear resistance of the conveyor belt.

Wire rope: In some high-strength and high-load applications, wire rope may be used as a reinforcement material inside the conveyor belt to provide higher tensile resistance.

3. Core layer:

The core layer is mainly the basis for the entire conveyor belt structure. It is usually made of rubber or other elastic materials to protect and wrap the reinforcement layer to ensure the flexibility and durability of the conveyor belt.

Therefore, the bucket elevator conveyor belt is composed of a cover layer, a reinforcement layer and a core layer. Zaozhuang Jinflex Rubber & Plastic Technology Co., Ltd. has 50 years of production experience and supports personalized customization. Interested bosses are welcome to purchase.

If you want to know more about conveyor belts, please leave a message in the comment area or contact us directly by email “enquiry@chinajinflex.com”