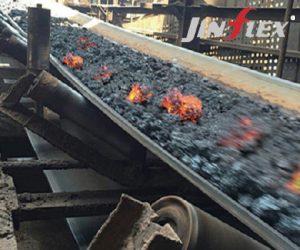

The high temperature conveyor belt cover rubber is a specially designed high-performance material with excellent heat resistance and wear resistance. Its excellent heat resistance can effectively resist the damage caused by high temperature environment to the conveyor belt, prevent cracks, hardening, cracking and other problems on the surface of the conveyor belt under long-term high temperature, thereby extending the service life of the conveyor belt. This cover rubber is processed through a special heat treatment process to minimize the aging speed and shrinkage rate of the conveyor belt at high temperature, ensuring that the conveyor belt can still maintain good elasticity and structural stability under harsh temperature conditions, and reduce the frequency of maintenance and replacement.

Heat-resistant conveyor belts are widely used in various industrial fields that need to transport high temperature materials, such as cement plants, steel plants, fertilizer plants, heating stations, power stations, etc. The production processes of these industries are usually accompanied by high temperature environments. Traditional conveyor belts are prone to performance degradation under such conditions, and even lead to production stagnation. The emergence of high temperature conveyor belts can effectively solve this problem, improve production efficiency and reduce downtime losses, making enterprise operations more stable.

Zaozhuang Jinflex Rubber & Plastic Technology Co., Ltd. has 50 years of production experience and is a conveyor belt manufacturer integrating R&D, manufacturing, marketing and service. The company has MA certification for all products and enjoys a high reputation and good reputation. Interested bosses are welcome to leave a message.