Skeleton material: High-strength fibers such as polyester (EP) and nylon (NN) are used, which have both high strength and flexibility.

Fabric structure: Optimized structure, such as straight warp and weft, reduces wear, and improves strength and flexibility.

Production process:

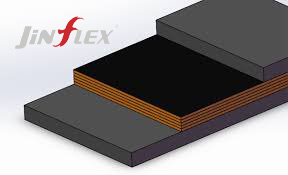

Multi-layer design: Enhances strength and wear resistance, disperses stress, improves flexibility and life.

Vulcanization treatment: Enhances rubber strength and wear resistance, and ensures good combination of rubber and fabric core.

Material properties:

Rubber elasticity: Absorbs and disperses stress, protects the fabric core, and adapts to complex environments.

Flexibility: Improves structure, maintains stable shape and performance, and prolongs life.

In summary, layered fabric core conveyor belts are widely used in many fields due to the optimization of their materials, structures and processes. Zaozhuang Jinfulex Rubber and Plastic Technology Co., Ltd. has 50 years of experience in conveyor belt production. Interested bosses are welcome to purchase.