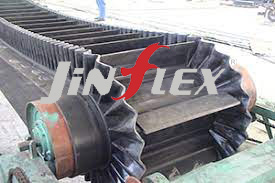

The main function of the sidewall conveyor belt is to optimize the material conveying process and ensure that the material can be transported from one place to another stably and efficiently. The following is a detailed analysis of the role of the sidewall conveyor belt:

1. Prevent material leakage and significantly improve efficiency

During the material conveying process, especially bulk materials such as coal, ore, grain, etc., it is often easy to slide from both sides due to the vibration or excessive inclination angle of the conveyor belt. This will not only cause material waste, but also reduce the carrying capacity of the conveyor belt, thereby affecting the overall conveying efficiency. The sidewall conveyor belt effectively solves this problem by setting baffles on its side. The baffle can firmly fix the material to prevent it from sliding from both sides during the conveying process, thereby significantly improving the carrying capacity of the conveyor belt, ensuring the continuity and stability of material conveying, and thus improving the overall conveying efficiency.

2. Adapt to a variety of complex working conditions and widely used

The design of the sidewall conveyor belt enables it to be suitable for various complex working conditions, including large-angle or even vertical conveying occasions. This feature makes the sidewall conveyor belt widely used in many industries such as mining, coal, metallurgy, chemical industry, and grain. In the mining and coal industries, sidewall conveyor belts can easily cope with steep slopes and complex geographical environments to achieve efficient material transportation. In the metallurgical and chemical industries, sidewall conveyor belts can transport high-temperature and highly corrosive materials to ensure the stable operation of the production line. In the grain industry, sidewall conveyor belts can ensure the clean and hygienic transportation of grain to avoid pollution and waste.

3. Reduce material loss and reduce costs

The sidewall conveyor belt significantly reduces material loss by preventing material leakage. This not only reduces the production cost of the enterprise, but also improves the utilization rate of resources. At the same time, since the sidewall conveyor belt can maintain the continuity and stability of material transportation, it also reduces equipment failures and downtime caused by material scattering, thereby further reducing the maintenance cost and production risk of the enterprise.

Therefore, the sidewall conveyor belt has the advantages of preventing material leakage, improving efficiency, adapting to various working conditions, and reducing material loss. The main function is to prevent materials from slipping off the sides of the conveyor belt during transportation. The side of the sidewall conveyor belt is equipped with baffles, which can effectively improve the stability of the conveyed material, especially suitable for inclined transportation or occasions where bulk materials need to be prevented from overflowing.

Zaozhuang Jinflex Rubber & Plastic Technology Co., Ltd. has the MA certification for all products. Its products have won the “National Only Quality Gold Award” and enjoy a high reputation and good reputation. At the same time, its products are exported to more than 50 countries including the United States, Canada, Brazil, Chile, Argentina, Australia, the Middle East, Southeast Asia, etc., and are well received by users.

If you are interested in our products, please call us!