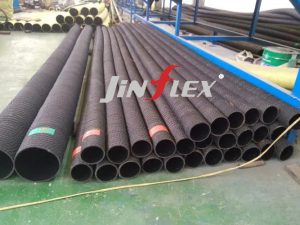

In the field of fluid transmission, four-layer steel wire wound hose has won the favor of many users with its unique performance and wide range of applications.

Today, let’s talk about why this hose is so indispensable.The core advantage of the four-layer steel wire wound hose lies in its unique four-layer steel wire structure. This structure not only improves the pressure resistance of the hose, enabling it to withstand working pressures up to 60MPa, but also enhances the wear resistance and impact resistance of the hose. Even in high-pressure, high-speed, and high-frequency fluid transmission environments, the four-layer steel wire wound hose can maintain stable performance.

Today, let’s talk about why this hose is so indispensable.The core advantage of the four-layer steel wire wound hose lies in its unique four-layer steel wire structure. This structure not only improves the pressure resistance of the hose, enabling it to withstand working pressures up to 60MPa, but also enhances the wear resistance and impact resistance of the hose. Even in high-pressure, high-speed, and high-frequency fluid transmission environments, the four-layer steel wire wound hose can maintain stable performance.

The softness and flexibility of this hose are also a highlight. Although it is reinforced with steel wires internally, it still maintains good flexibility and can adapt to various complex installation environments and space constraints. This makes the installation of the four-layer steel wire wound hose more convenient in small spaces or curved parts, greatly improving work efficiency.

Four-layer steel wire wound hose has a wide range of application scenarios, covering heavy industrial fields such as petroleum, chemical industry, electric power, and metallurgy, as well as daily life fields such as agricultural irrigation, urban water supply, and fire protection. In these fields, four-layer steel wire wound hose plays a decisive role, providing users with efficient and reliable fluid transmission solutions.

To sum up, the four-layer steel wire wound hose has become an indispensable tool in industry and daily life due to its excellent performance and wide range of application scenarios. Choosing a four-layer steel wire wound hose is not only a guarantee of equipment performance, but also an investment in work efficiency and safety.