Fiber braided oil hose is mainly composed of three parts: inner rubber layer, reinforcement layer (high-strength fiber braided layer) and outer rubber layer.

Inner rubber layer: generally made of high-quality synthetic rubber material, with excellent oil resistance, can withstand the erosion of various oil media for a long time without swelling or softening.

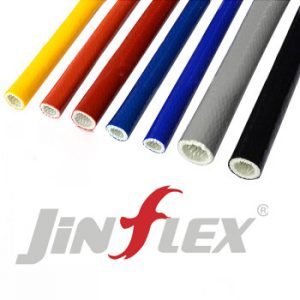

Reinforcement layer: woven with high-strength fiber, which is the key to the pressure and tensile resistance of the oil pipe. Common braided materials include polyester (PET) fibers, etc., which can effectively disperse external pressure and protect the inner rubber layer from damage.

Outer rubber layer: made of wear-resistant and weather-resistant rubber material, the main function is to protect the hose from mechanical damage and environmental influences.

This structural design makes the oil pipe have the advantages of corrosion resistance, oil resistance, wear resistance, and pressure resistance.

Fiber braided oil pipes are mainly distributed in the automotive industry: used in the fuel and lubrication systems of automobile engines, as pipelines for transmitting fuel and lubricating oil; petrochemicals: transporting various corrosive media such as acids, alkalis, salts, etc. in chemical production; marine engineering: as oil pipelines for offshore drilling platforms, offshore oil field operating platforms and other equipment.

The advantages of choosing our Zaozhuang Jinfu:High-quality materials to ensure stable and reliable product performance; diversified specifications and models to meet the needs of different application scenarios; high-quality after-sales service to solve customer worries.

If you want to know more about fiber braided oil pipes, please visit our official website for inquiries. We are Zaozhuang Jinflex Rubber and Plastic Technology Co., Ltd.

You can also contact us directly by email “enquiry@chinajinflex.com”.